When buying a cutting board, there are two key factors to consider: the wood grain and the type of wood the board is crafted from. In this post, we discuss the most popular types of wooden cutting boards.

Wooden cutting boards are typically constructed of strips of wood that are glued together. Typically each strip is from the same species, although artisanal boards often utilize different species to provide color contrast. The choice of which side of the wood faces up will dictate the board’s overall appearance.

There are three grain styles to choose from: end grain, edge grain, and face grain. Below we explain the distinctions between these three styles. We also outline their pros and cons, and help you decide which one best suits your needs.

End Grain vs. Edge Grain vs. Face Grain – Which to Choose?

What are End Grain Cutting Boards?

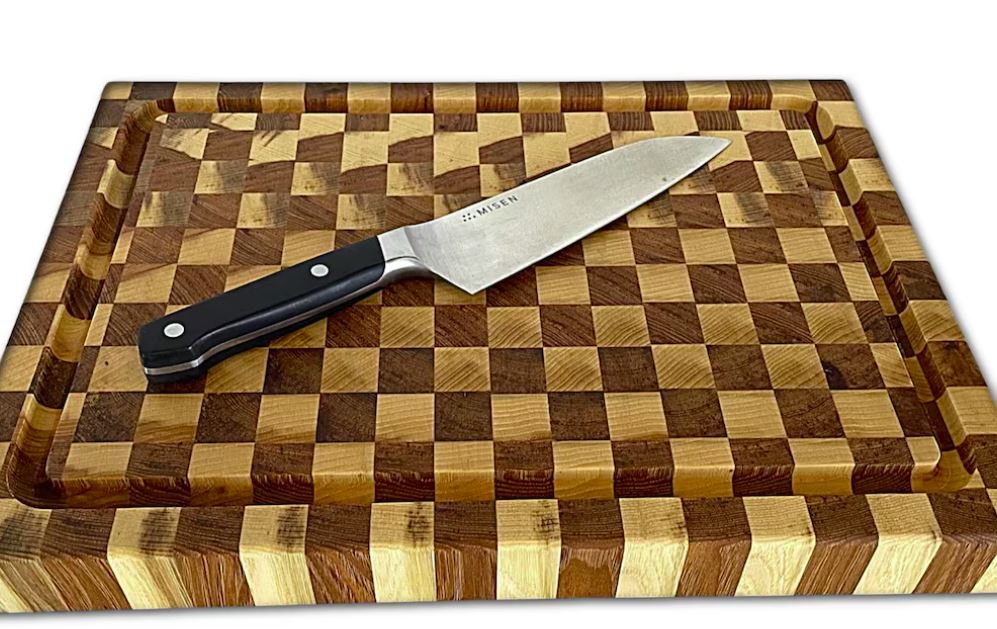

Starting off our discussion on types of cutting boards, let’s explore end grain cutting boards – often referred to as butcher blocks. Butcher block is renowned as the sturdiest and possibly the most preferred grain style for wooden cutting boards.

In end grain construction, cutting board manufacturers use cuts from a piece of lumber that reveal the tree’s growth rings. The boards are then assembled using small blocks with the end pieces facing upwards, often in a checkerboard pattern.

End Grain Cutting Boards are Self-Correcting

This type of cutting board results in a unique surface: the end of the wood fibers forms the cutting surface, which results in a self-correcting quality. When you use knives on this type of surface, they slice between the wood fibers instead of across them. As the knife lifts off the board, the wood fibers naturally close back together.

Imagine turning your hand in a way that resembles a knife and “cut” through a thick grassy lawn. Your hand moves parallel to the blades of grass which then spring back to their original position once your hand is lifted back up. However, cutting across the side of the lawn causes the blades of grass to bend or break.

This same principle applies to wood fibers on an end grain cutting board.

Advantages of End Grain Cutting Boards

There are many advantages to an end grain cutting board. These include:

- Concealed Cut Marks: When knives cut through the wood fibers, rather than across them, the fibers have the ability to naturally close back up. This results in fewer visible knife marks and scratches on the board’s surface.

- Durability: These boards are well-suited for heavy chopping and butchering tasks on a consistent basis. As with all wooden cutting boards, regular conditioning is essential to ensure their longevity and performance over time.

- Knife-Friendly: End grain boards allow knives to sink slightly into the wood, helping them retain their sharp edge for longer periods. This reduces the need for frequent sharpening.

- Robust and Heavy: End grain boards typically have a thickness ranging from 2 to 2.5 inches, imparting substantial weight and stability during use. This thickness also enhances their resistance to warping, provided they receive regular conditioning.

Disadvantages of End Grain Cutting Boards

There are some disadvantages of end grain cutting boards. These include:

- More Seams: As previously mentioned, the construction of end grain boards involves many individual pieces, resulting in a greater number of glued seams. This can pose issues if the board isn’t consistently maintained or if it’s obtained from a less reputable source, as these seams may develop cracks over time.

- Higher Cost: The construction of end grain boards requires many individual wood pieces, necessitating more cuts and additional glue to assemble. This intricate work and the extra materials contribute to their higher price tag.

- Frequent Conditioning Required: The exposed wood fibers on the surface make end grain boards more prone to oil evaporation compared to edge and face grain cutting boards. Consequently, they demand more frequent oiling or conditioning to prevent drying out.

In addition to the above, we have noticed that the end grain boards we tested tended to be slightly more porous due to the exposed grains. As a result, they may be more susceptible to odor retention and staining if not properly cleaned after use (think chopping onions or garlic).

Best Uses for End Grain Cutting Boards

Compared with cutting boards of other grain types, end grain cutting boards (or butcher blocks) generally excel with:

- Preserving High-End Knives: If you use high-quality kitchen knives, end grain cutting boards are the top choice to maintain sharpness and maximize longevity.

- Heavy-Duty Cutting and Butchering: These boards are ideal when you anticipate frequent heavy chopping, butchering or carving of large cuts of meat.

What are Edge Grain Cutting Boards?

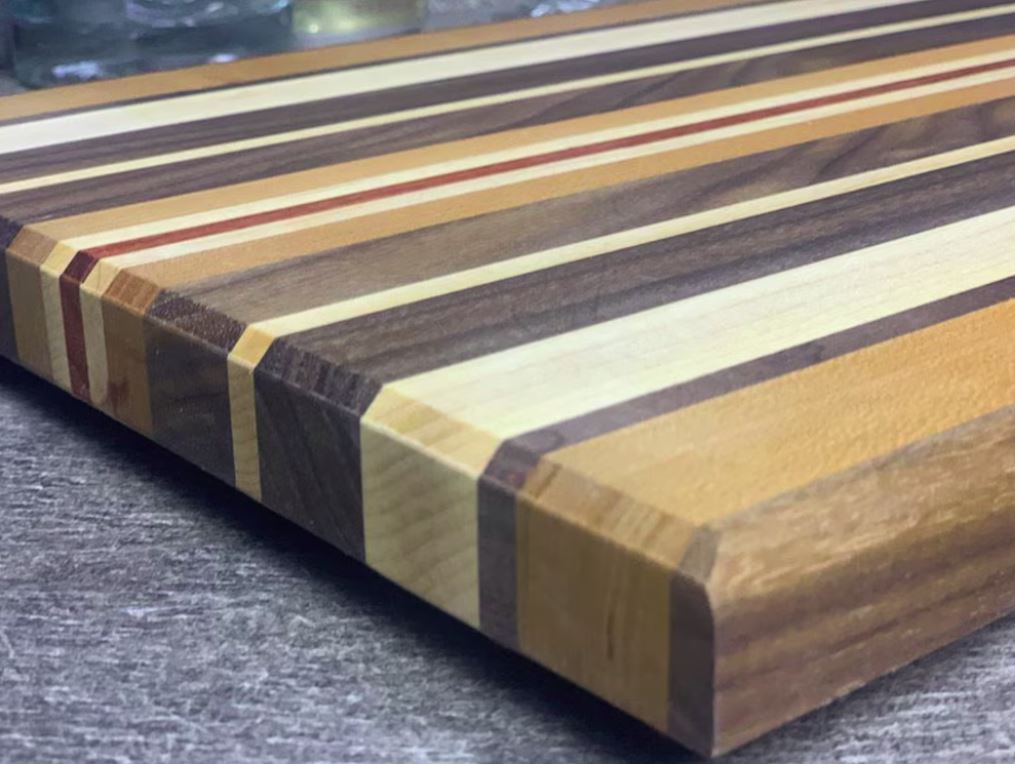

Now, let’s delve into edge grain cutting boards. In the context of a piece of wood, we define the narrow sides as the edge grain. Cutting boards crafted from this grain style involve gluing the flat, wide side of the wood together, with the edge pieces facing upward.

An edge grain cutting board boasts a distinctive striped pattern. Typically, these pieces run the entire length of the board, showcasing the continuous grain pattern and the innate beauty of the wood.

Unlike end grain boards, however, there is no inherent “self-healing” property when cutting on this type of board since knives slice across the wood grain.

Advantages of Edge Grain Cutting Boards

There are many advantages to an edge grain cutting board. These include:

- Ease of Maintenance: While all wooden cutting boards require periodic sealing, edge grain boards demand less frequent oiling over time when compared to their end grain counterparts.

- Reduced Moisture Absorption: Edge grain boards exhibit slower liquid absorption compared to the exposed fibers of end grain boards. As a result, they are more resistant to stains and tend to dry faster after washing.

- Cost-Effective: Edge grain boards are less intricate to manufacture, making them a more budget-friendly option when selecting a wooden cutting board.

- Long-Lasting: When properly maintained, edge grain cutting boards can serve you well for many years, offering long-lasting durability.

Drawbacks of Edge Grain Cutting Boards

However, there are some disadvantages of edge grain cutting boards. These include:

- Moderate Knife Impact: An edge grain board may dull your knives faster compared to an end grain cutting board. That said, it remains a gentler option in comparison to face grain, plastic, or glass cutting boards, which are harsher on your knife edges.

- Knife Marks are More Apparent: Cutting across the grain can result in more visible knife marks. However, regularly applying a high-quality cutting board oil can help mitigate their visibility.

Best Uses for Edge Grain Cutting Boards

Compared with cutting boards of other grain types, edge grain cutting boards excel with:

- Daily Culinary Tasks: Edge grain cutting boards are excellent choices for your everyday culinary needs, ideal for light to medium food preparation tasks like chopping vegetables or carving and slicing small to medium-sized meats.

- Elegant Serving: Thinner and lighter edge grain boards often double as stylish serving platters for items like cheeses, crackers, and more, adding a touch of sophistication to your presentations.

- Handling Moisture-Heavy Foods: Thanks to their reduced moisture absorption, these boards are well-suited for cutting various fruits as well as other items with high liquid content.

- Ease of Handling: Their moderate weight makes edge grain boards easy to transport between the sink and the countertop, providing convenience in the kitchen.

What are Face Grain Cutting Boards?

Rounding out our discussion of the types of cutting boards, let’s explore face grain boards.

Face grain cutting boards stand out as the simplest among the three grain styles to construct. When we consider a single piece of wood, we refer to the wide sides as the face grain. These boards are fashioned from either a single solid piece of wood or two pieces securely joined along the narrow edge.

Face Grain Cutting Boards are Visually Stunning

What sets face grain cutting boards apart is their stunning visual appeal. They feature minimal seams and showcase a pristine, smooth grain across the entirety of the board.

Consequently, face grain boards are often used as serving platters or personalized through engravings, making them excellent gifts.

Advantages of Face Grain Cutting Boards

There are many advantages to an edge grain cutting board. These include:

- Aesthetic Appeal: These boards showcase the complete wood grain, lending them a distinctive character that’s visually appealing.

- Budget-Friendly: Among the three grain styles, face grain boards are the most cost-effective option due to their straightforward construction.

- Enhanced Moisture Resistance: Face grain boards exhibit lower liquid absorption, making them more resilient against stains and spills.

Drawbacks to Face Grain Cutting Boards

However, there are some disadvantages to a face grain cutting board. These include:

- Susceptible to Warping: Face grain boards typically have limited thickness, usually around 1” think. This makes them thinner than end or edge grain boards, and more susceptible to warping if not properly maintained.

- Knife Impact: Like edge grain boards, face grain boards can have a blunting effect on knives as they cut through the wood fibers. Nevertheless, they are a gentler option compared to harder surfaces such as plastic, glass, or bamboo cutting boards.

- Prominent Knife Marks: Due to the single, uniform wood surface, knife marks on a face grain cutting board are highly visible because you cut across the wood fibers.

Best Uses for Face Grain Cutting Boards

Compared with cutting boards of other grain types, face grain cutting boards often excel with:

- Use as Serving Board: A face grain cutting board can make a great serving board. Hands down, it is our favorite style among the various board types for a nice cheese or charcuterie platter. It is also an affordable option as well.

- Everyday Light Use: Face grain cutting boards work well when used for light kitchen tasks

Read More >> 10 Best Cutting Boards for Japanese Knives

Types of Cutting Boards: Summary

When it comes to the most popular types of cutting boards, there are three grain styles to choose from. These include end grain, edge grain, and face grain. We touched on the differences between these surfaces, reviewed their pros and cons, and offered advice on which to choose based on your needs.

It is important to properly care for your board regardless of the style you select. Cleaning after each use will mitigate the retention of odors (think chopping onions), while period sealing with a quality food-grade oil will ensure the longevity of the board.

Regardless of the grain type, cutting boards are indispensable tools in the kitchen. They also can be used as serving platters, and make great gifts. Grab one today for your next holiday party.

Besides wood, glass cutting boards are another popular option. Check out our post highlighting the pros and cons of glass cutting boards.